Biomass pellet machine is mainly used to make granulated fuel by crushing, extruding, molding and other processes of biomass raw materials by mechanical force. According to the different molding methods, Biomass pellet machine can be divided into two types: flat model biomass granulator and ring model biomass granulator.

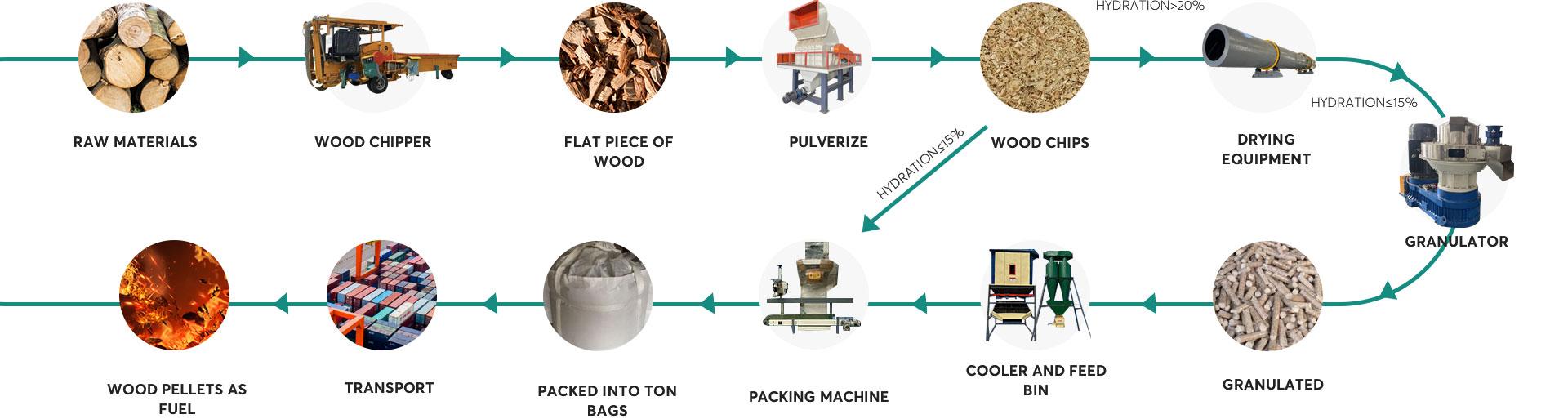

The working principle of the biomass pellet machine is based on mechanical compression and shaping technology. In the working process, the biomass raw material is first subjected to crushing treatment to meet certain particle size requirements. The pulverized raw material is then fed to the forming area of the granulator, where the raw material is compressed into a high-density granular fuel by the pressing action of the nip and the ring die. The formed particulate fuel has higher density and strength, which is convenient for storage and transportation.

The pellet fuels made by biomass pellet machine have a wide range of applications, mainly including the following aspects:

Civil heating and domestic energy: biomass particulate fuels can be used for domestic heating, hot water supply and other areas of domestic energy, replacing traditional coal and gas and other energy.

Industrial boiler: biomass particulate fuel can be used as the main fuel of industrial boiler, replace traditional energy such as coal, reduce atmospheric emissions and pollution.

Biomass power plant: biomass particulate fuel can be used in the power generation process of biomass power plant, to achieve large-scale utilization of biomass energy.

With the global attention to renewable energy and the improvement of environmental awareness, the market prospect of Biomass pellet machine and its granulated fuel is broad. Especially in China, with the advance of comprehensive management policy of energy and environment, biomass pellet fuel, as a clean and renewable energy form, will receive more and more attention and application. At the same time, the continuous progress of Biomass pellet machine technology and cost reduction will further promote its market development.

|

Model |

Power(kw) |

Spindle speed(r/min) |

Capacity(kg/h) |

Quality(kg) |

|

TY75-3 |

B35Y280S-4 |

138 |

1000-2800 |

5000 |

|

TY75-3 |

B3Y315S-6 |

144 |

1000-2800 |

4500 |

|

TY90-4 |

B35Y280M-4 |

138 |

1200-2000 |

5000 |

|

TY90-4 |

B3Y315M-6 |

144 |

1200-3000 |

5500 |

|

TY45-2 |

B35280S-6 |

144 |

700-1200 |

3500 |

|

TY37-2 |

B3Y250M-6 |

144 |

600-1100 |

3000 |

Henan Tengyu Machinery Equipment Co., Ltd. is a professional manufacturer of production and sales of mechanical products. In the 1990s, it was named Zhongyuan as a country that produced all kinds of agricultural machinery.