Wood crusher is mainly used to finely break all kinds of wood processing scraps such as wood, branches and boards into sawdust of different specifications, so as to be further utilized or used as raw materials for other wood products. These sawdust is widely used in pulp, particleboard, MDF, bamboo products, sponge, thermal insulation materials and other industrial raw materials production.

The Wood crusher is driven by a motor to make the rotor (the shaft is equipped with a blade or hammer) rotate at a high speed. When the material is uniformly fed into the crushing chamber, the material is cut, torn and hit by the action of the high-speed rotating blade or hammer, and is gradually broken into smaller particles. At the same time, due to the effect of centrifugal force, the materials collide with each other in the crushing chamber, which further promotes the crushing of the materials. The crushed material is screened through the screen, and the qualified material is discharged from the screen hole, while the larger material is kept in the crushing chamber for further crushing.

Wood crusher typically consist of:

Feed port: used to feed the material to be crushed into the crushing chamber.

Grinding chamber: is the main working area of the wood crusher, which is equipped with rotor, blade or hammer, etc.

Rotor: The shaft is equipped with a blade or hammer, which is driven by a motor to rotate at a high speed.

Blade or hammer: Used to cut, tear and strike material.

Screen: Located under the crushing chamber, used to screen the crushed materials. The size of the mesh can be adjusted as needed.

Discharge port: qualified materials are discharged from the discharge port after passing through the screen hole.

Motor: to provide power for the sawdust mill, drive the rotor for high-speed rotation.

Frame: structure used to support and fix the entire sawdust mill.

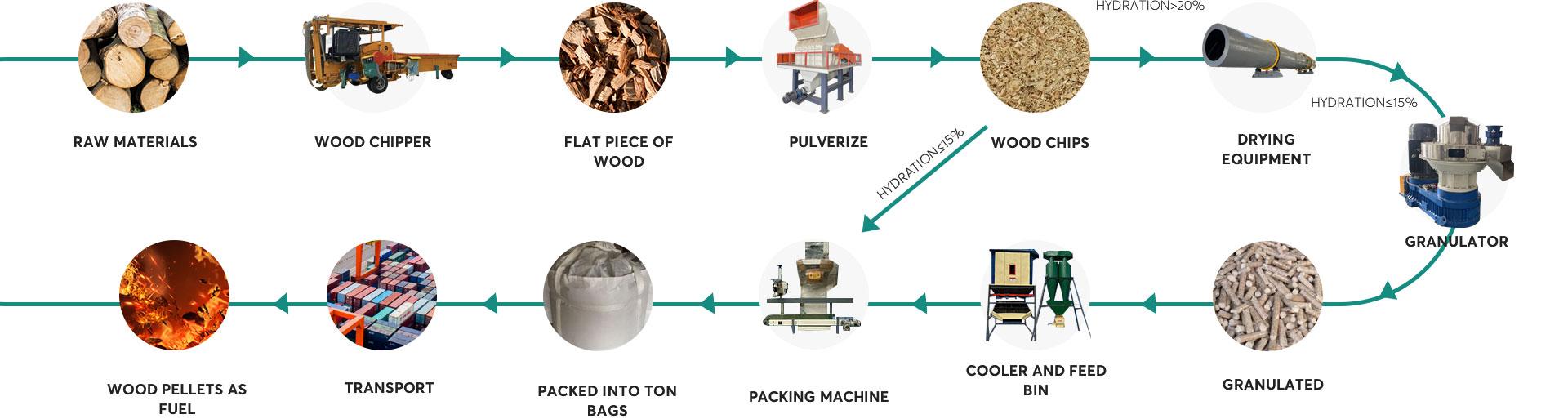

The pellet fuels made by biomass pellet machine have a wide range of applications, mainly including the following aspects:

Civil heating and domestic energy: biomass particulate fuels can be used for domestic heating, hot water supply and other areas of domestic energy, replacing traditional coal and gas and other energy.

Industrial boiler: biomass particulate fuel can be used as the main fuel of industrial boiler, replace traditional energy such as coal, reduce atmospheric emissions and pollution. Biomass power plant: biomass particulate fuel can be used in the power generation process of biomass power plant, to achieve large-scale utilization of biomass energy.

|

Model |

Main Power(kw) |

Feed opener size(mm) |

Blade qty |

Hammer (qt) |

Hourly capacity(kg) |

Overall dimension(mm) |

|

500 |

18.5-22 |

280×500 |

4 |

12 |

800 |

1500×650×850 |

|

600 |

30 |

300×600 |

4 |

12 |

1000-1200 |

1500×700×1000 |

|

700 |

37 |

320×700 |

6 |

18 |

1500 |

1550×750×1050 |

|

900 |

55 |

320×900 |

8 |

30 |

2500 |

2000×1100×1300 |

|

1000 |

4-75 |

350×1000 |

8 |

30 |

3000 |

2000×1100×1300 |

|

1200 |

4-90 |

350×1000 |

9 |

39 |

3500 |

2000×1900×1800 |

|

1500 |

4-110 |

350×1200 |

12 |

48 |

5000 |

2000×2300×1005 |

Henan Tengyu Machinery Equipment Co., Ltd. is a professional manufacturer of production and sales of mechanical products. In the 1990s, it was named Zhongyuan as a country that produced all kinds of agricultural machinery.